Crane Grab Buckets

- Home

- Product

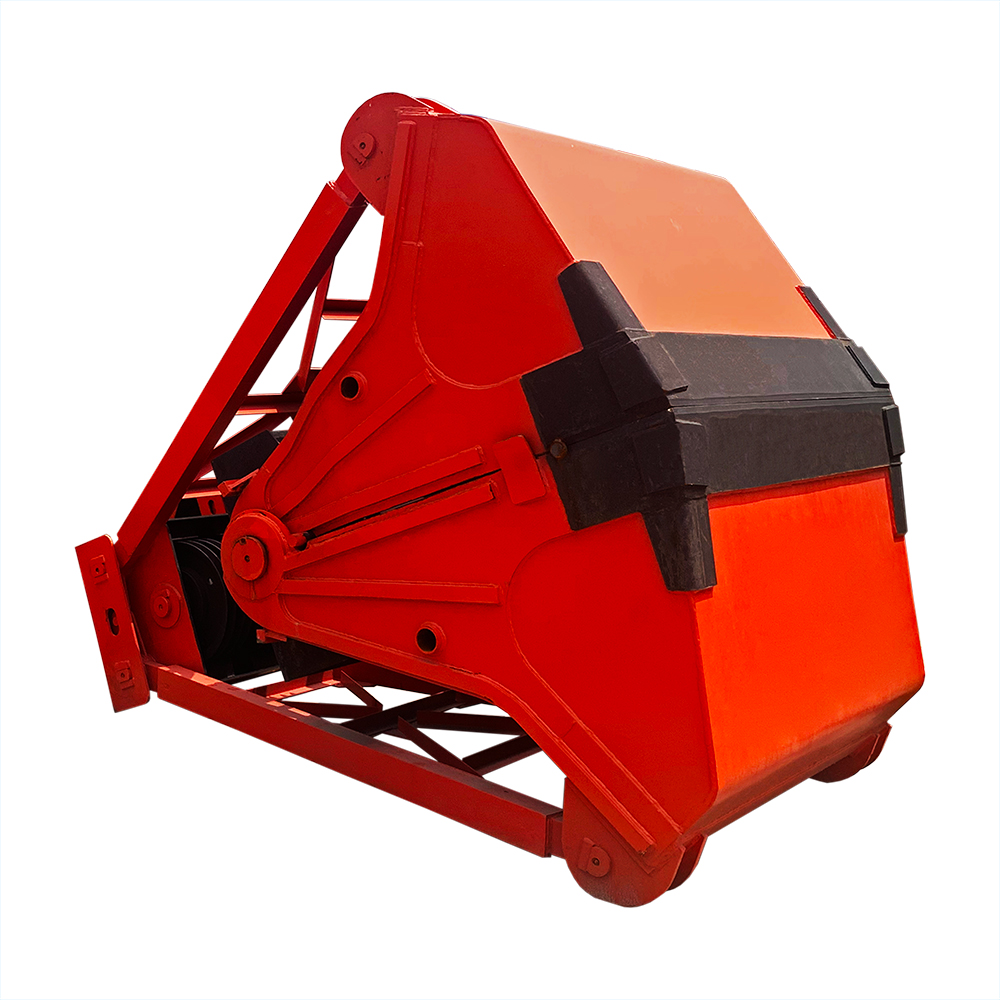

Crane Grab Buckets

Crane grabs are specialized tools that attach to cranes, enabling efficient and secure lifting and transportation of bulk materials. They come in various configurations to suit different applications, with two of the most common types being the clamshell grab and the orange-peel grab.Based on the above two forms of crane grabs, we will choose different drive forms for you according to your specific use scenario, including two-rope, four-rope, hydraulic, as well as electric winch closure mechanisms.

The orange-peel grab consists of multiple jaws or tines that resemble the segments of an orange peel. It is designed to handle irregularly shaped and bulky materials with ease.

The clamshell grab features two equally-sized buckets or shells that open and close like a clamshell. It is typically made from high-strength steel to withstand rigorous use in demanding environments.

Product Description

The crane grab is an essential attachment designed for various lifting and handling operations. Its robust construction and versatile functionality make it indispensable in industries such as construction, mining, shipping, and waste management. The crane grab is engineered to enhance productivity, ensure safety, and streamline operations, making it a valuable addition to any material handling equipment inventory.

Technical Parameter

| Parameter | Specification |

| Bucket Type | Clamshell, Orange Peel, Electro-Hydraulic |

| Capacity | 0.5 to 15 cubic meters |

| Material | High-strength steel, abrasion-resistant steel |

| Weight | Varies based on capacity and type, typically 500 kg to 5000 kg |

| Max Load Capacity | Up to 25 tons |

| Opening and Closing Mechanism | Hydraulic, Electro-Hydraulic, Mechanical |

| Number of Shells | 2 (Clamshell) or 4-6 (Orange Peel) |

| Operating Pressure | 160 to 350 bar (for hydraulic systems) |

| Rotation Angle | 360 degrees (optional) |

| Teeth Type | Standard, Rock, or Customizable |

| Grab Force | Adjustable, up to 50 kN |

| Control System | Manual, Remote Control, or Automated |

| Power Supply (for Electro-Hydraulic) | 380V, 50Hz, 3-phase or customized |

| Construction Material | Cast steel, Forged steel |

| Durability Features | Wear-resistant plating, Reinforced edges |

| Maintenance Requirements | Regular lubrication, Inspection of hydraulic hoses and seals |

| Usage Applications | Bulk material handling, Scrap handling, Rock handling, Waste management |

| Environmental Adaptability | Suitable for extreme temperatures, corrosion-resistant |

Advantages

- Provides a secure grip on materials, minimizing spillage.

- Available in various sizes and capacities to match specific job requirements.

- Can be equipped with wear-resistant edges for increased durability.

Application

- Clamshell Grab Application Ideal for handling loose materials such as sand, gravel, coal, and grain. Commonly used in dredging, loading, and unloading operations at ports and construction sites.

- Orange-peel Grab Application Perfect for handling scrap metal, waste materials, and demolition debris. Frequently used in recycling facilities, scrap yards, and waste management operations

About Our Factory

Certification

Huasui Advantages

Great Strength

The company has a registered capital of 120 million and focuses on the production and sales of lifting equipment.

Rich Experience

Years of industry experience to help you achieve personalized customization needs and product solutions.

Supporting Equipment

Perfect process flow and supporting production equipment, independently complete all processes to reduce costs.

After-sales Service

The product provides warranty service, free repair for quality problems, and free technical support.

Packing & Delivery

Product Recommendation

Electromagnetic Chuck Lifter

An electromagnetic chuck, also known as an electromagnetic lifter, is a device that uses ...

Crane Wheels

Wheels are widely used in the Crane manufacture, the port authority, transportation, Airl...

Crane Hooks

Heavy weight gantry crane overhead crane 50ton 100ton hook with safety latch is one of th...